How Audions Were Built

|

|||||

If you have never read the story of Lee de Forest's journey from initial experiments to finally achieving success with his amplifying vacuum tube, the Audion, then you might want to take a few minutes to look over this article. It was published in a 1947 issue of Radio-Craft magazine as part of the 40th anniversary of the invention that changed the electronics world. With so many other things which are nowadays very commonplace, we tend to not think about or appreciate the ingenuity and effort that went into them. It is one thing to make incremental improvements in an existing technology, but to conceive of and created an entirely new realm of science is quite another. As with Albert Einstein's relativity and Robert Goddard's liquid-fueled rockets, and the Wright brothers' powered aeroplane, there was no significant work to draw upon other than fundamental principles that were used as building blocks of the ground-breaking discoveries. The amount of reasoning, deduction, and creativity that is a part of such things is truly amazing. Take a look at the table of contents for many more of the articles. How Audions Were Built

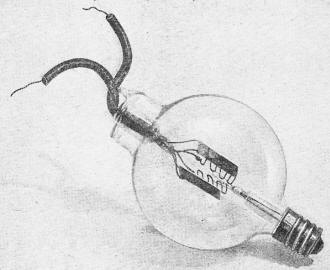

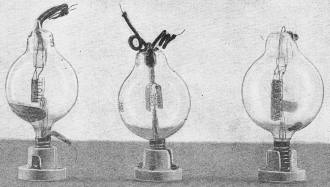

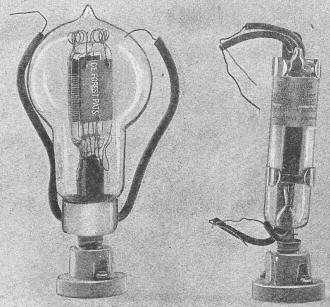

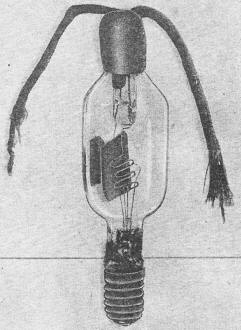

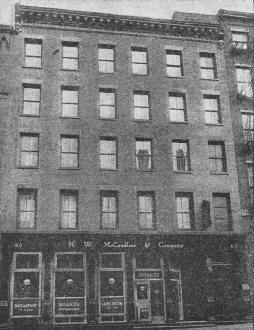

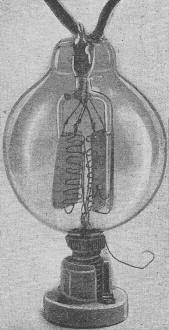

You and your factory foreman ... put the invention in practical working shape and handed to the world a useful device ... a more meritorious act than the simple dreaming that it could be done." So wrote Lee de Forest's assistant, C. D. Babcock, to H. W. McCandless on December 9, 1913. Behind this letter lies one of the greatest success stories of the early days of radio, a story unfortunately not too well known. Henry Wallace McCandless, guiding genius of the firm of H. W. McCandless & Company, Inc., was graduated in mechanical engineering from the University of Illinois in 1890. In 1895 he founded his company and engaged in the manufacturing of miniature incandescent lamps at 67-69 Park Place, New York City. In the ensuing years he built up a reputation for being able to make special lamps of all types. His work and reputation were such that large lamp manufacturers referred their orders for special lamps of un usual design or characteristics to him. Because of his knowledge of materials and the techniques of handling them, he was able to fulfill the most bizarre requests. As he developed new techniques for handling glass and metals, he also made lamps of his own design for special applications. Few realize that even in the field of surgery part of the progress made in those days may be attributed directly to the lighting developed by McCandless. Experimental Pre-Audion Tubes When Dr. de Forest and his assistants were struggling with the idea of the audion, it was but natural that they should turn to the foremost lampmaker of the day to have their models made. Toward the latter part of 1905, C. D. Babcock, one of de Forest's assistants, came to McCandless with a crude lamp and asked if he could duplicate it. The sample had a flat anode and was unbased. Babcock said that de Forest was working on a wireless telegraph detector, that he had tried an experimental form using a gas flame, and was now desirous of replacing the gas flame by an incandescent filament. Accepting Babcock's order, McCandless cut the sample apart and made six copies of the model. These bulbs had a carbon filament and a nickel anode. Two days later Babcock came back and brought de Forest with him to discuss the bulbs. While the first order was a duplication job, subsequent orders were for bulbs made up in accordance with sketches, usually extremely rough ones, provided by Babcock or de Forest, who called these devices "audions." These were all essentially two-electrode devices (filament and anode) and the lead to the anode was brought out through the wall of the glass bulb, sometimes at the top, sometimes at the side. The First Order for Audions In the fall of 1906, de Forest and Babcock ordered a large quantity of tubes, all alike. When McCandless received the large order, he assumed that these men had at last found exactly what they wanted. However, they returned in December of that same year and asked him to make up more models, this time with a zigzag wire grid between the filament and the plate, or "wing" as it was called at that time. Early double-filament, double-grid and double-plate audion, now owned by Louis G, Pacent. Three evolutionary steps. Left is 1908 audion, center a 1910, and right a 1912 type. The earliest of these "grid-type" audions had carbon filaments of the treated type, the grids and wings were of nickel, and the bulbs were cylindrical. They had single filaments, but double filaments were soon introduced, and the records of the McCandless Company show that the first double-filament types were made in 1906. The first double-element type (plate and grid on each side of the filament) was made in April 1909, but the single-element type continued to be made for some years thereafter. These double-element tubes were known as "double audions," and were sold by de Forest at a higher price than the single-element type. A number of these double audions are shown in the attached photographs. Contributions by McCandless It was evident to McCandless that these men were experimenting and as usual he drew on his wealth of knowledge to make suggestions as to how the tubes might better be made. The earliest tubes had all the elements mounted on a single stem, although the leads for the grid or wing, and sometimes for both, came through the side of the bulb instead of through the "press." McCandless and his shop superintendent, Jacob C. Grogan, felt that the audion would not become a commercial product until the tubes were designed with the grid and wing on one stern, and the filament on another. The purpose of this was, first, to keep the leads separate and, second, to save the loss of audions due to burning out of wire filaments during exhaust. With the double-ended assembly it was easy to cut off the stem of the bulb, splice on a new neck and seal in a new filament and stem, thus saving the bulb. While this development work was going on, McCandless was working on another project. For a long time he had wanted to make a satisfactory incandescent lamp to operate at two volts, so that it could be used on a single storage cell. The characteristics of the available carbon filaments would not permit this, with the filament diameters available. The filament had to be so short that only the center part glowed, the temperature of the end portions being reduced by conduction of heat through the supports. Improvements in Filaments In 1906 a friend brought from Germany one of the newly-developed tantalum-filament, 110-volt incandescent lamps, which were then little known in the United States. McCandless broke open this lamp, and using approximately 1/55 of the length of the 110-volt filament, made up a two-volt lamp which was successful. He then tried to obtain additional tantalum wire from Siemens & Halske, with the understanding that it was for use in lamps operating at less than ten volts filament. Although he made some progress in the early stages, negotiation was never successful because of patent difficulties. He did manage, by working through the Association of Lamp Manufacturers, to get limited amounts of this wire from the General Electric Company. McCandless decided to try tantalum-filaments in the audion. It was a good inspiration, since it improved the electrical characteristics considerably, but it had its disadvantages. It was not stable in position. When heated it would not remain in a plane, but would twist around to such an extent sometimes as to touch the other elements. The important thing was that it could be made to operate at four volts. Carbon filaments required at least six volts for satisfactory operation. Courtesy G. F. J. Tyne Left - An early de Forest "Singer Type" audion. Note the metal base. Right - An Ultraudion with Hudson filament mounted in an adapter to permit operation in candelabra socket. About this time tungsten filaments came into the picture, and McCandless , ever on the lookout for methods of improving the quality of the audions he made, tried them. The tungsten filament of that day proved to be little better than carbon and far inferior to tantalum. The suggestion was made - by whom McCandless does not remember - that a tungsten filament be used because of its rigidity, but that it be wrapped with tantalum to get good emission. Always open to suggestions, McCandless tried this expedient. It was successful. The combination was as good electrically as pure tantalum and as good mechanically as the carbon filament. Soon after the first tubes were made for de Forest, in 1905-1906, a young man came to McCandless and wanted to buy some audions. McCandless consulted de Forest who told him: "Sure. Sell them to him." This McCandless did, and the word spread, so that more and more tubes were sold on an over-the-counter basis. One of these customers, who first came to buy shortly after McCandless had introduced the tantalum-wrapped tungsten filament, was Dr. Walter G. Hudson, an enthusiastic amateur, then chief chemist for du Pont. McCandless showed him the audions with the tantalum-wrapped filament and told him that the wrapping was an extremely tedious and time-consuming operation. Hudson bought some of the tubes, and after he had used them came back to McCandless and said: Very early type of three-electrode audion, made in 1907 and 1908. Reconstruction of the 1907 appearance of the building at 67-69 Park Place, New York City, where the first Audion was made by McCandless. "I have an idea. Let me try it, and if it works I'll patent it and go fifty-fifty with you if it proves saleable." Hudson's plan was to grind the tantalum to powder, make a paste of the powder by adding a binder, and applying the paste to the loop of the tungsten filament. Hudson provided the paste and the audions made in this manner were very satisfactory. In fact the "Hudson filament" type soon became the "standard" audion. During these years of development work on the audion, McCandless was not focusing his attention on materials alone. He was also experimenting with the shape of the tube and the positioning of the elements therein. Better Pumping Equipment The early audions were made with the vacuum ordinarily obtained in the incandescent lamp of that day. When McCandless began to manufacture miniature lamps, he used an exhaust pump of the "Packard" type. Later he added so many improvements to this that it became known as the "McCandless pump." At that time no pressure gauge was used on the pumping equipment. To determine when the proper vacuum was attained the mercury valve which checked the back-rush of air into the pump was watched. The tubes were pumped until practically no bubbles appeared at that point. The bulbs were checked for leaks with a high-tension spark-coil device, commonly used, by incandescent lamp manufacturers for that purpose. De Forest kept demanding higher and higher vacua in the audion. Later, for higher vacua, the tubes were baked in an oven to a very high temperature while still on the pump. In some cases the bulbs were heated, by the direct application of a Bunsen flame, almost to the collapsing point. This was done to expel all the gas occluded in the glass bulb. A few years later, in August 1910, McCandless replaced his pumping equipment with two rotary pumps of the Gaede type (not the Gaede molecular pump). A third such pump was added in February 1911. De Forest continued to demand higher vacua in the audion and sometimes returned the bulbs for re-evacuation, complaining of a lack of "sensitiveness." Grogan insisted that the lack of sensitiveness was caused by pumping the tube to too high a vacuum. This was particularly the case while de Forest was on the West Coast with the Federal Telegraph Company, where he was trying, in 1912, to make the audion function as an amplifier. Detector vs. Amplifier Here is a confusion of the terms" sensitivity" and "output." In the case in question de Forest, on the West Coast, was trying to get high output by operating at high anode voltage. The tubes would not give output, hence he said they were not "sensitive." What he meant was that he could not get the desired amplification at high power levels because of ionization of the residual gas. The gaseous tubes advocated by Grogan and operated at low anode voltage would detect lower voltages but would not give high power output. McCandless made a number of audions for the Federal Telegraph Company while de Forest was with them. in the fall of 1912 de Forest came east with a view to interesting the telephone company in the amplifying properties of the audion, for its use as a telephone repeater. After he had demonstrated the device, de Forest left the apparatus with the engineers of the Western Electric Company, and gave them permission to purchase additional bulbs from McCandless for their experiments. McCandless made for them two types of bulbs. The first was a tantalum-filament double audion, and the second a single audion, but having larger elements and a larger bulb, with a longer, higher-voltage filament of tantalum. These tubes are shown in the photographs. The larger elements were used at the suggestion of Grogan. Courtesy G. F. J. Tyne A 1916 tube, last of the screw-based audions. It was made at de Forest's Highbridge plant. Some time prior to 1912 the Marconi Company took official cognizance of McCandless' work on the audion. Mr. R. W. Sammis, then chief engineer of the Marconi Company, in a preliminary telephone conversation offered to give McCandless the job of making Fleming valves for his company, provided he would stop making audions for de Forest. Sammis later wrote McCandless a letter transmitting to him a copy of the Fleming patent and stating that it covered the audion and in fact any type of rectifying vacuum detector. McCandless consulted an attorney, Charles McCandless (not a relative, however) , and they studied the Fleming valve patent. Meantime, after the telephone conversation, but before the letter from Sammis, McCandless became very much concerned over the situation and wrote de Forest about it. De Forest replied, on March 2, 1912, giving a list of the patents covering the various embodiments of the audion, and assuring McCandless that he was fully protected. McCandless obtained copies of all the patents, and after due consideration decided to continue the manufacture of audions. Sales to the general public were negligible after 1913. De Forest started to make tubes himself at his High Bridge plant and "bootleg" manufacturers started up. McCandless never advertised or solicited trade in audions. He continued to make special bulbs for de Forest or any other customer who came to him with a problem which was a challenge to his genius. He sold his business to the Westinghouse Company in 1914 and entered their employ as manager of the Westinghouse Special Lamps Division. To this day the concluding paragraphs of Babcock's letter written about that time must bring back a stirring flood of memories to McCandless. The Tribute from Babcock "The mechanical and electrical development of the device from those, crude designs of mine to the perfect instrument of the present day should and does stand as a monument to the skill, patience and technical knowledge of your Mr. Grogan. Particularly valuable was his disclosure to de Forest that the audion should not be exhausted to a vacuum known as 'hard,' but rather should be 'soft,' that single fact took the device from the ranks of failures and put it in the category of successes. "Facts are stubborn things, and the above are some of the stubbornest in the history of this instrument. The great pity is that the thing never became more generally used so that you could reap the reward due you for the part you and your staff played in its development."

Posted August 20, 2020 |

|||||

By Gerald F. J. Tyne

By Gerald F. J. Tyne