Electronics - at Work |

||

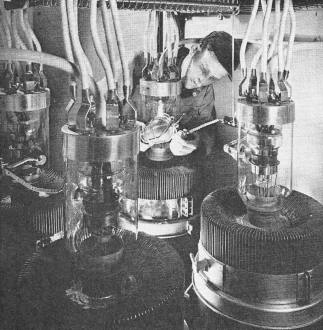

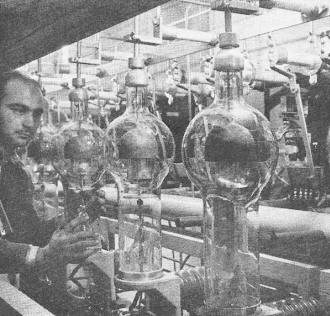

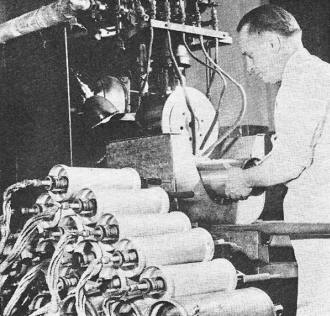

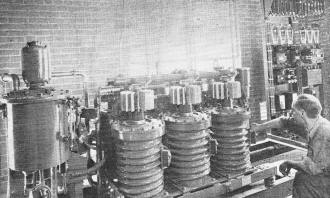

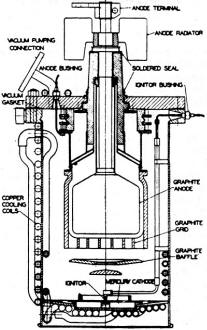

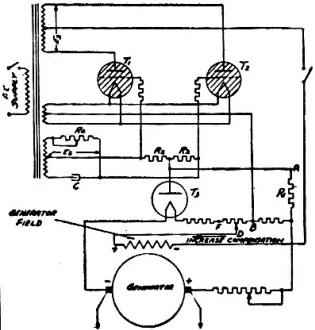

Glenn Bradford's delve into "Electronics - at Work" is deep and wide. In this June 1945 issue of Radio News magazine, he hits on many of the main issues being debated in the mid-1940s regarding what role electronics would and should play in regrouping society following World War II. Major advances in mechanics and electronics were made during the war, and a huge potential workforce for dealing with designing, manufacturing, selling, and servicing of a vast array of promised appliances and gizmos was "out there" looking for an opportunity. In spite of that, indecision and reluctance to take risks plagued industries scurrying to adapt from a (sometimes forced) wartime production mindset back to a consumer-centric mode. Whereas the government funded conversion to defense products, it was up to companies to make the transition back. This is a very interesting insight into the situation. Be prepared for an introduction to many new terms. Electronics - at Work Two of these 50,000 watt air-cooled modulating tubes at KDKA are spares. By simply pushing a button, the operator can put them into service without interrupting transmission. By Glenn Bradford Electronic tubes and equipment for power conversion will play a leading role in postwar production. The field of electronic application is in a furor, as can be seen by a casual survey of the advertising pages of any technical or semi-technical magazine - for that matter, any general magazine - popular or technical. This condition has undoubtedly been promoted by the need for war-time secrecy - there is nothing that can be said about so much that our advertisers frequently say much about nothing! "Electronics" has become an advertising catchword and a magic cure-all. which, after the war, is expected to reduce all work, both mental and physical, to the mere exertion of pushing a button! In view of this situation, which to workers in other fields must appear positively baffling and before attempting to find a "place" for electronics in power generation, it seems desirable that the term "electronics" be defined, and discussed, to place it on a solid engineering basis. Men in other fields may then be in a better position to assay the future effect of electronics on their own field of interest, without becoming electronic engineers. There are two ways in which electronics differs from power electrical engineering in its viewpoint of the electron. First, in electronics we are concerned primarily with the actions of free or individual electrons relatively unaffected by their surroundings, while in power electrical engineering we think of these electrons en masse, obeying laws which are statistical averages of the behavior of the separate electrons. These large groups of electrons are affected by conditions in the conductors in which they flow, such as electrical resistance. A second, and possibly more important difference in viewpoint, is with respect to the velocities at which the electrons travel. In electronics we are interested in devices in which electrons travel unimpeded at speeds of thousands of miles per second; in power electrical engineering the electrons rarely move at rates greater than a few inches per second. These high-voltage rectifier tubes change alternating current into direct current for radio transmission. Automatic relays are used for changing tubes without interrupting broadcasts. These metal-encased Ignitrons convert alternating current into direct current needed to make aluminum for our fighting planes. Workman is shown seam-welding metal jacket to tube. This Ignitron installation for changing alternating current into direct current, provides efficient conversion, is compact, and has high overload capacity. Having no major moving parts to require maintenance, the Ignitron delivers power continuously 24 hours a day. It is easily installed and can operate automatically and unattended. Ignitron rectifiers are today supplying dependable d.c, power for a great and growing number of America's vital electrochemical plants, and aluminum production processes. Because of the close relationship of the individual electron to electronics we may well ask - what is an electron? Present-day knowledge on that point does not go far. We can predict what an electron will do under certain circumstances but know nothing of its shape, size, or internal construction. Combustion engineers would be in much the same situation if they knew only the British Thermal Unit value of their boilers, but would be at a loss to understand what went on in the combustion process. We do know that an electron is the smallest particle of matter, and that all matter contains electrons. We know that it takes 5x1029 electrons to weigh a pound - an inconceivable number. Our most important knowledge is that an electron carries an electric charge, is in fact our smallest-known indivisible unit of electricity. This charge is so small, however, that it takes 6x1018 electrons passing through every second, to heat a 100-watt, 110-volt lamp to incandescence. Since an electron is an electric charge, then a flow or movement of electrons constitutes an electric current, whether it be in an electron tube, a lamp filament, or a motor. We have seen that an electric current is the same, regardless of the material through which it flows, but it is the difference in the "material" of the path that furnishes us with a rather simple definition of electronics. Electronics may be defined as the field of devices which function by reason of passage of electrons through gas or vacuum. This definition establishes the fundamental distinction between power electrical engineering and electronics as a difference in the nature of electrical conducting path. It is seen to exclude conduction of electric current through solids or liquids, such as our power transmission and electrolytic processes, but to include all other cases of conduction of electric current (or electrons), such as our conventional radio tubes, gas-filled tubes, X-ray tubes, fluorescent lamps, neon lamps; and switches and circuit breakers in the power field. While the latter are not usually thought of as electronic devices, yet their operation is dependent on controlling the flow of electrons through air and they appear to be correctly included within the field of the definition. Why Electronics? It appears that much of the present-day design and development work in the electronics field (military needs aside) is being done by the sales manager and the advertising man - the engineers are too busy with other things. It is doubtful if these men are, on the whole, well-grounded enough in this field to do much thinking other than of the "wishful variety." This almost inevitably leads to developments that may be physically possible, but economically unrealizable. Dress these developments in a veil of pseudo-censorship, thin with a liberal application of overgrown advertising budget, and serve to the public as a full-page spread in their favorite publications, and you have a fairly accurate case history of many of the "new" electronic developments. It can probably be agreed that an electronic device can be designed to perform the most complicated operation dreamed of by the most highly-gifted press agent. An electronic control could be built to operate the most cantankerous boiler, under the most vicious load cycle, holding the steam temperatures, with never a waver in the steam pressure line, and having the entire performance of the boiler operator limited to pushing the start button. Since there are already on the market automatic control systems which approach this ideal, why would the electronic system be preferred? An examination on an engineering basis discloses only three reasons why engineers, as business men, will purchase electronic control or metering devices. These three fundamental reasons are: 1. The electronic system can perform an operation no other device can do. 2. The electronic system can perform an operation better than any other system. 3. The electronic system is cheaper than any other system. Electronic equipment can often perform operations impossible by any other apparatus. Such equipment, smoke recorders are an example, will find a ready sale at any price consistent with the value of the result, and will be bought not because they are electronic but because there is no other way. Electronic equipment can often perform operations better than some other types of equipment; the new, fast, continuous temperature recorders are examples, and will be purchased because a better result is obtained at a price consistent with performance. Electronic equipment unfortunately is not always cheaper than competing systems. When it is cheaper it will be purchased for obvious reasons. If a piece of electronic equipment cannot be justified by any of the above, it will not be sold. Newness or novelty does not determine the design of modern boiler and turbine rooms. To state the matter in another way, electronics can do any job - but it will not always be justified by the engineering and economic factors involved. Electronics is usually assumed to have been born in 1885 with the discovery of the Edison effect: that electric current could flow in a vacuum. It was first applied about 1887 in the magnetic blowout on street car controllers. Another application at almost the same time was the carbon motor brush, in which conduction is suspected of being electronic in nature. These two applications are credited with having saved the infant street railway from extinction. We can say that electronics was applied almost before it was born. The first real attempt to make use of electronics as we now think of it occurred about 1930-31, but the development failed to take hold. It is interesting to examine the reasons for that failure in an effort to use that information in estimating the stability of the present situation. First, it is believed that the development failed because the market had not been prepared; the customers had not been educated to the idea of using a so-called "fragile" glass radio tube in the plants and apparatus. Second, the apparatus was frequently poorly designed and poorly applied, by engineers with inadequate training in electronics and other fields. It was not the fault of electronics but that of a complete lack of understanding of the operating conditions under which the equipment was to be used. Equipment in a state little better than that of the original laboratory model was sent out and expected to operate under conditions existing in the steel mill or the boiler room - naturally it failed to operate as it did in the manufacturer's laboratory. The designer had great faith in his electronics, but too little knowledge of what it must do. What of the Future? The war has apparently provided an ample testing ground to convince the skeptics that electronic equipment is not fragile or delicate. Satisfactory service in ships, tanks, and aircraft should be ample evidence that the electron tube can safely be allowed to take its place in industry. The customers have been sold - if not oversold. The great danger to the present electronic development, and to industry in general, lies in the second reason for failure of the 1930-31 venture. It can be briefly stated as a lack of men trained to design, sell, apply, and maintain electronic equipment for industrial use. Electronic equipment unfortunately is different from other electrical equipment, and the power-trained electrical engineer is usually not equipped to handle it. There are believed to be fewer than 1000 men in the United States and fewer than 100 men in Canada today, equipped by training and experience, able to design and apply electronic devices to industry in general. These men must be trained not only in electronic devices, but it is much more important that they also be trained and experienced in the processes, equipment, and techniques used in industry, to be able to give the purchasers adequate technical advice. It is this shortage of capable engineers, to which the radio-trained technicians released from the Armed Forces will be able to add little, that is the real obstacle over which our forthcoming electronics boom may stumble. Fortunately, there are certain factors in the equipment design, which, if understood by the customer and applied at the time of a purchase, may prevent a misapplication and purchase of unsatisfactory electronic equipment. An electrical engineer thinks of a resistor, an inductor or a capacitor, as a circuit constant, which can be purchased as having a certain value and which will have that same value at all times. An electron tube is not such a precision device. When new, they are considered satisfactory if they do not vary more than about plus or minus 20% of the standard rated values. During life the tube characteristics are continually changing, causing changes in circuit performance, unless the design was given a sufficient safety factor. Failure to allow for the electron tube as a circuit variable is one reason electrical engineers with power training frequently have trouble designing and applying electronic devices. A device may work perfectly with a certain set of tubes at the factory, and later when the customer must replace some of the tubes it becomes inoperative. Another difficulty occurs in not allowing for the change of tube characteristics during the life of the tubes, and as a result the calibration of the device is found to be in error later, even though perfectly correct at installation. It is almost always possible to design electronic devices to be independent of the characteristics of the tubes used. As a rule it calls for a higher order of engineering ability, and may raise the cost slightly. The results will be found worth the additional cost, since a well-engineered design is indicated. A design of this nature means that a tube may change its characteristics over a very considerable range without affecting the performance. In one example, a tube operated for over five years, or about 45,000 hours. When removed the tube tested extremely low, far below the point at which it would be usable in a radio receiver, yet at no time had the recorder shown any calibration inaccuracies. When a new tube was inserted, the recorder continued to operate without change. Performance substantially independent of tube characteristics is especially important in a control. A change in tube characteristics may cause a shift in the control point, or a tube failure may cause the control to run away, if the design is not made independent of the tube. If the operating instructions mention periodic checking of calibration, or provide an adjustment to be checked periodically, then the instrument is probably not designed to be independent of the tubes. As a check, insert various tubes and note the effect on the calibration, and for a control, remove one of the tubes, simulating a complete tube failure and note the effect on the control operation. Then ask, is that effect desirable? Mechanical Features The, weak spot in many electronic applications is not in the electronic circuits but in the mechanical parts used to actuate the electronic control, or in the mechanical parts used to perform the desired operation. These are the features that the electronic engineer will know least about, because they may be peculiar to one application. In an application of electron tubes to a printing register control it took six weeks to work, and a complete redesign of parts of the machine to make the electronic register control function. The customer's application engineer failed to allow for the instantaneous, high-speed action of the control and had to reduce weights and strengthen parts before the mechanical part of the machine would stand up. During this time the electronic circuits had operated perfectly at all times. Possible Power Applications in Power Generation Having surveyed some of the factors which should underlie the application of electronics to any field, let us now ask - what is its future in power generation? If we remember the three basic reasons for the application of an electronic device we can find a number of present and future applications, in which electronics will definitely be a factor. Smoke measuring and recording happens to be an excellent example of an application which can be made in almost no other way than by electronics. There are, at the present time, several photoelectric smoke recorders on the market, operating on various principles, but essentially they cast a beam of light across the stack, striking a photoelectric cell, and the output current or voltage of this cell is recorded as a function of smoke. When we try to decide what function of smoke this is, we get into trouble. First, what is smoke? Until this question is settled by engineers, independently of the politicians, we will have no really satisfactory measuring of smoke density. Certainly the Ringelmann chart, with its reliance on purely subjective readings by the human eye, affected by the color of the smoke, the cloudiness of the sky, the position of the sun, is not an engineering measurement. Second, many smoke-recorder engineers, designers, and smoke inspectors, seem never to have heard of Lambert's law which states that the amount of light absorbed by the smoke is an exponential function of the thickness of the smoke column. The smoke from a 20-foot stack will absorb four times the light absorbed by a column of the same smoke in a 10-foot stack, giving a reading of much more smoke when actually there are exactly the same number of particles per cubic foot. These are examples of some of the difficulties besetting the application of an electronic device in a new field. They are not the fault of electronics, but you will frequently hear electronic smoke recorders blamed for not reading correct smoke densities. What is smoke? Another point at which electronics is entering the power field is in the measurement of temperature. For many years the intermittent, step-by-step type of temperature recorder was standard and did an excellent job. Electronics entered the picture and it was found possible to improve on even the best of the preceding types by elimination of most of the mechanical moving parts, by the elimination of the delicate galvanometer, or by removal of the step-by-step action. There are now recorders on the market retaining all the accuracy of the older models, but giving continuous movement of recording pens, without a galvanometer, and with no mechanical parts more complicated or troublesome than an electric motor. Electronics has made possible these improvements, and there are enough potential developments now available to insure a continued advance in this field after the war. These new developments will take the line of improved versions of temperature recorders using electronic tubes as actuating elements. We can also look forward to the complete end of measurement of radiant temperatures by putting something in the furnace or pipe. The new way will involve electronic means, and we will measure temperature by looking at the hot body. We will use such devices, not because they are electronic, but because they are better. The use of electronics in the measurement of flow is not so far advanced. Means have been proposed for this but so far they do not look too promising. This excludes the transmission and telemetering of flow readings electronically. The latter field is already well developed, there being a number of devices on the market. We can expect a continued development of electronic transmission devices, especially with the large war use of position indicators, but so far no one has proposed a practical method of eliminating the orifice in the pipe lines and of performing the flow measurement electronically and external to the pipe. The position indicator or flow transmitter is a device well able to make maximum use of the advantages offered by electronics. Electronic devices require very small or zero input torque, they can operate at high speed, and the currents and voltages encountered are suitable for transmission over telephone wires as is frequently desirable. This is an excellent and almost always dependable application of electronics. It would seem that a thorough investigation of the possibilities of such devices should be made by the power industry, especially as to their advantages in transmitting readings to the boiler and turbine recorders and control panels, in contrast to running high-pressure piping and tubing into these panels. This will become increasingly important as operating pressures and temperatures rise. What has been said of flow measurement applies almost equally well to pressure measurement. While we have very satisfactory recorders of dynamic pressures, as encountered in reciprocating engines, we do not as yet have a truly electronic method of measuring static pressures as encountered in steam-generating stations. There are several possible paths of approach to the problem, and it seems reasonable to expect ultimate success, with the line of development taking advantage of electronic means. The field of automatic control offers possibly the largest opening for electronic equipment in power generation. The advantages of zero input torque, high speed, limitless output torque, and almost unbelievable precision should give electronics a great opportunity. It is here, however, that the greatest engineering skill in application will be required, if electronics is not to receive an irreparable setback at the very beginning. The war is giving us electronic control devices in considerable variety, but their application to industrial control will not be as easy as the press agents would have us believe. The requirements of performance, safety, and dependability are very high and it will be in the application, not in the electronic circuits themselves, that the difficulties will be encountered. Watch for them there and allow the electronic engineer to worry about the tubes. The first applications will probably be made on control problems where speed is an essential. This is an advantage of the electronic system over competing systems which will be capitalized. Another advantage is simplicity of mechanical moving parts reducing maintenance. The use of electric wires instead of oil or air tubing for transmission will be cheaper and more advantageous in certain cases. But in every case the selection of electronic control will be based on the three fundamental reasons, and not because it is electronic. At the present time several companies can offer partial systems of automatic control, from simple on-off systems to the more complicated modulating forms of control. As the war ends we will find an increasing variety of this apparatus available, possibly involving greater use of more complicated control systems such as second and third derivative control, functions which can be easily introduced into electronic control systems. Is There a Place for Electronics? To one familiar with the field, it seems obvious that power generation offers a very large number of potential applications for electronics, because electronics has very definite advantages to offer over other types of equipment. The advances it has forced in the field of temperature measurement are an indication of the possible advantages to be gained by the adoption of electronic methods. Acknowledgment The author wishes to thank Professor J. D. Ryder for much of technical research work contained in this article.

Posted July 13, 2021 |

||