How Binoculars Are Made

|

|

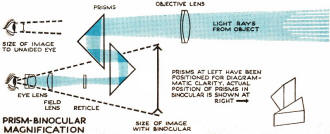

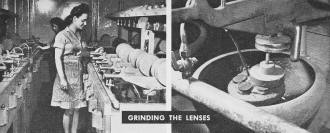

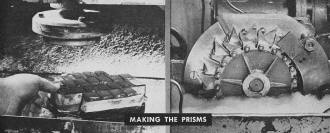

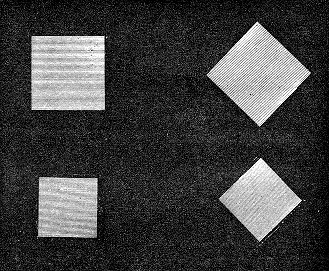

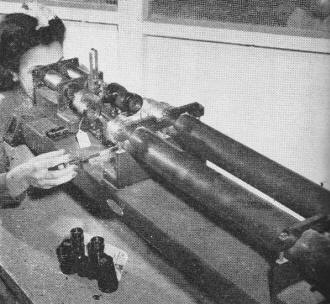

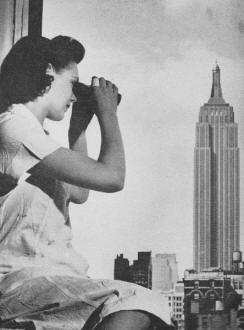

How Binoculars Are MadePhotographs taken by Robert F. Smith at Universal Camera Corp., New York, N. Y. Fighters on sea and land need these powerful prism instruments... Here's the story of the mass-production methods that supply far-seeing eyes for warriors. America's front-line fighters must see more than meets the eye. In every battle zone - land, sea, and air - they're called upon to perform ocular miracles. It's their job to unmask camouflage, dissect heat and haze, and scan hopeless distances to get information that spells victory. They must spot the enemy before he sees them. And they're doing it with American-made prism binoculars, now in mass production for the first time. The ingenuity that made this possible has been rewarded with an "E" presented by the Army and Navy to the Universal Camera Corporation of New York. On the verge of ruin in 1940, when war blacked out its European film markets, this firm rallied to take a top place among war industries. Before the end of 1943, its production hit 11,000 binoculars a month for our armed services. That means turning out 150,000 optics (lenses and prisms), to say nothing of fabricating and assembling more than a million metal parts. Grinding the Lenses Grinding the objective lenses of prism binoculars is done mechanically with wax-surfaced wheels while a solution of red oxide of iron flows over the work (above right). Batteries of these machines, whose grinding wheels are automatically controlled as to speed and pressure, now mass-produce lenses formerly turned out laboriously by skilled craftsmen. So precise are the machines that they can smooth down a lens to a tolerance of 1/100,000 of an inch. During milling and polishing, lenses get 116 inspections Making the Prisms Here a group of prism blanks, made of light barium crown glass, are being placed in a diamond cutting machine. Precisely machined metal blocks are used as holders for the prisms, which are set into recesses and helf fast with wax and binding strips After being rough-cut, the prism blanks are set in the niches of a milling machine that revolves in a bath of grinding fluid. As the machine turns, it brings one side of each prism into contact with a polishing disk, which is beneath fluid's surface With the faces and sides of the prism now carefully polished, the next step is to bevel all its edges. This is a hand operation in which the prism is held against a grinding wheel, while a stream of ordinary water is played over the stone as a grinding fluid A clamp that will hold it firmly in the binocular is about to be placed on a prism. At this point, the prisms have been paired off so that one having a plus deviation in the verticality of transmitted light is coupled with one of equal minus deviation Assembly The housing for a binocular is cast from scrap aluminum, machined, then covered with strips of Vinylite, which has the texture of leather. A soldering iron fuses strips into one piece Universal has tossed out all the old, traditional methods of making binoculars. Otherwise, it still might be slogging along neck-deep in red ink. It has turned a highly specialized art into a task for machines tended by unskilled labor. It has speeded the whole cycle of production to a degree undreamed of heretofore. In preparing flawless faces of lenses or prisms, the basic steps are roughing, grinding, and polishing. The custom is to rough out each glass blank separately, then mount them in a mold. After that, for the grinding and polishing operations, the mold is spun against abrasives. When one side is ground, it is turned over and ground on the other side. This procedure goes on through all stages of grinding and polishing. It's tedious and time-consuming. A set of prisms is here being placed in one barrel of the binocular. Note that the other barrel is covered to prevent accumulation of dust, which must be guarded against at every stage of assembly To reduce loss of light caused by surface reflection, optical elements in binoculars are being coated experimentally with magnesium-fluoride vapor. Tests indicate coated pieces transmit about 99 percent of light At Universal's plant, sparks fly by application of a three-in-one process. Blanks are mounted on a mold that carries them through roughing, grinding, and polishing as one continuous operation for each side, What's more, molds are so designed that unskilled hands can easily insert blanks. This simplifies the formerly complicated task of mounting. For the final polishing - a job that once required fine judgment and skilled hands - Universal automatically applies a liquefied oxide that not only does just as well, but also minimizes chances of human error. In all, this new method of making binoculars has established a manufacturing precedent that will endure long after the war is over. Objective lenses, consisting of two lenses cemented together and fitted into metal rings, are immediately screwed into place after a suction tube (bottom) removes dust Assembly of the binocular is completed with the mounting of the eyepiece. This part comprises the field, or collective, lens, a short barrel, and two lenses cemented together to form the eye lens For the present, however, its task is to speed the flow of urgently needed binoculars to our fighters on land and sea. With the aid of these precision-built instruments, Americans in all services will be able to see better and fight better. Inspection An illuminated screen containing square's on which fine lines are drawn is used to test the ability of the binocular shown above, to distinguish two parallel lines when they subtend five seconds of arc at the instrument. At the left, a military binocular is checked to see if its two ocular axes are parallel. The girl above is using an auxiliary scope, an ordinary telescope placed over one of the eyepieces of a binocular to magnify its normal resolution. A binocular is also sighted on actual object to test clearness, color dispersion, and astigmatism. And, finally, it is placed in a tank of water to see how waterproof it is, and then dropped six feet into a sand pit to test its ability to withstand rough handling

Posted November 6, 2023 |

|