|

July 1965 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

I am always amazed when reading

articles like this one on "The Art of Xerography" at how the engineers and scientists

who develop (pun intended) these system manage to think up the processes and materials

required to make everything work so well, and then to make it manufacturable on

a mass basis. How did Chester Carlson discover that dyed

lycopodium powder, made from

creeping cedars, sprinkled over a waxed paper plate would create the likeness of

an original image - after, of course, rubbing a sulfur-coated metal plate with a

handkerchief and quickly exposing the plate to light transmitted through the glass

with a pattern on it. Electrostatics eventually came to play a big role in high

volume printing, as described here. I saw a video one time (can't find it now) of

a high voltage and chemical processed used on thin aluminum sheets used in newspaper

printing up through the 1970's for making masters. My father worked at

The Evening

Capital newspaper in Annapolis, Maryland, and I remember back in the 1960's walking

through the printing press area and seeing operators pounding away on typesetting

machines that assembled the lead die into lines of text, and from there the entire

process up through actual printing and folding of the newspapers. From around 1970

through 1974, I delivered those papers in my neighborhood on my bicycle. The subscription

cost was a whopping $2.10 per month (no Sunday edition), and collecting the money

from homeowners, done in person, was often frustrating because people would complain

about the cost. There were times I would see someone inside the house, but they

wouldn't answer the door to pay me. Then, when I'd come around again and it was

time for another month's payment, they would yell at me for not having collected

earlier so they wouldn't owe me $4.20. Some people really suck.

The Art of Xerography

Xerography, the laboratory curiosity reported by Electronics

World (then Radio News) in 1944, has been instrumental in creating a giant new industry

with sales in the hundreds of millions of dollars. The primary growth has been in

office copiers, but xerographic principles and processes are finding new and broader

electronic applications. This article updates the original.

By Chistopher M. Celent / Research & Engineering, Xerox Corporation

On October 22, 1938, a young physicist and patent attorney, Chester F. Carlson,

wrote "10,-22,-38 Astoria" on a piece of glass. Then, working in a darkened room

with another physicist as a laboratory assistant, they rubbed a sulfur-coated metal

plate with a handkerchief and quickly exposed the plate to light transmitted through

the glass. Next, they sprinkled the plate with dyed lycopodium powder, blew lightly

over it, and pressed a sheet of waxed paper to the paper surface. When the paper

was pulled free of the plate, the date and location were reproduced, and xerography

(Carlson called it "electrophotography") was born.

Carlson patented his invention and then set out to find some company to refine

and develop it. He knocked on the doors of some 20 to 30 companies without success.

But he persisted, and in 1944 succeeded in interesting scientists at Battelle Memorial

Institute. Battelle, a research organization located in Columbus, Ohio, agreed to

study the process.

In July, 1944, Radio News magazine (now Electronics World) heard about the invention

and published a technical analysis. A year later, Dr. John H. Dessauer; the research

director of a small company in Rochester, N.Y., read an abstract of the article,

then obtained and read the original article. Intrigued, he arranged for the president

of his company, Joseph C. Wilson, to visit Battelle.

Wilson was the president of The Haloid Company, then a small, moderately successful

sensitizer of photographic and photocopy paper and manufacturer of photocopying

machines. Wilson saw promise in the new idea and sponsored further research both

at Battelle and within his own company. In 1947, Haloid obtained partial rights

to the process and launched an intensive development program.

Thus the seeds of invention were sown, germinated, and nurtured. They were to

bloom in little more than a decade into a revolution in business office practices

and to catapult the little Haloid Company - renamed Haloid-Xerox, later Xerox Corporation

- into the ranks of the five hundred largest corporations in the United States.

Photomicrograph of xerographic image being formed. The large

positively charged carrier beads transport negatively charged toner particles to

the positively charged selenium-coated plate. The carrier beads are 100-200 times

larger than toner particles. (The dry developer powder is a special formulation

of small glass or sand carrier beads plus particles of black heat-fusible carbon.)

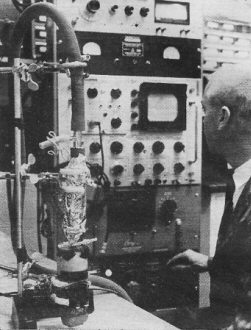

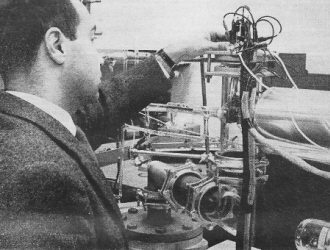

Laboratory test method to determine charge of individual toner

particles in xerographic developer. Powdered developer is placed in particle generator

at bottom. A loudspeaker vibrates the mix, randomly freeing charged particles. Some

of the particles are eventually drawn in a flow system through a capillary and a

drift-tube detector. The detector picks up a voltage proportional to the particle

charge. This voltage, indicating charge and velocity, is amplified and displayed

on oscilloscope.

Fig. 1 - The five basic steps in the xerographic process are

illustrated here.

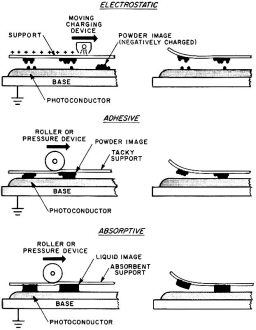

Fig. 2 - Image-transfer techniques. For electrostatic transfer,

the paper is given a charge opposite in polarity to that of the toner which makes

the image on the photoconductor. The image is thus attracted or transferred to the

copy paper. In the adhesive method, the paper to which the image is to be transferred

is coated with a sticky substance to which the toner adheres. In the absorptive

technique, the image on the photoconductor is liquid and when contacted by the paper,

the liquid will then be absorbed directly into the copy paper.

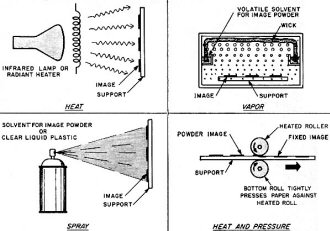

Fig. 3 - The various techniques that may be employed to fix the

image onto the copy paper. Refer to the text.

The xerographic process relies upon the deposition of electric

charges on a selenium surface. These charges are generated by a corona discharge

in air. The quadrupole mass spectrometer shown here is used to analyze ionization

in corona discharge.

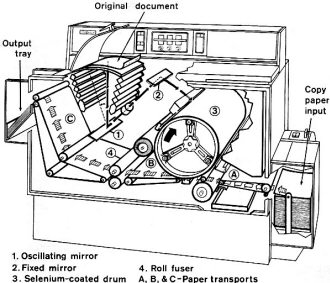

Fig. 4 - The operating principles of the 2400.

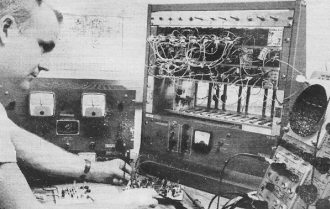

A new transistorized circuit for a data display simulator is

shown here being checked out in the company's laboratories.

A small analog computer is used by engineer to simulate a control

system for a copying machine under development. The mathematical model shortens

test time and increases confidence in the design of the control system.

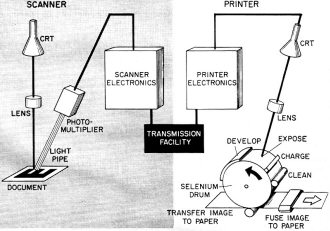

Fig. 5 - Operation of LDX (long-distance xerography) system is

shown here.

Why Xerography?

Chester Carlson's invention of xerography was no sudden flash of genius nor was

it an accidental discovery. When he "discovered" it he was seeking the solution

to a specific problem. Mr. Carlson in 1935 was working in the patent department

of P. R. Mallory and Company (and going to law school at night) and never seemed

to have enough carbon copies of patent specifications.

He could have found a copying machine in 1935, of course. There were, for example,

the Rectigraph machine (made, incidentally, by Haloid), blue-printing machines,

machines using the photographic processes, and others. But there were serious deficiencies

in the copies made by these machines and in the way these copies were produced.

The time it took to get a copy is a good example of the problems he faced. It

took about 30 minutes for each copy made and the machines of that day were so complicated

that it took special training to operate them as well as special locations for the

machines.

The process most likely involved handling "messy" chemicals which gave off offensive

odors. Other objections were that the copy was often faint, hard-to-read, and not

very permanent, or printed on hard-to-handle or flimsy paper Other machines required

specially prepared masters.

There were other reasons why copy was unsatisfactory. For example, some machines

would not copy certain colors. When the ball-point pen came into general use, it

was discovered that many of the machines would not copy it. Or, the copy came out

as white-on-black, white-on-blue, or in some other-than-usual color combination.

Then, too, only single sheets could be copied - often at some risk that the original

would be destroyed.

It is interesting to note that some of these faults were not really objectionable

back in 1935. As a matter of fact, most people then would have been satisfied with

almost any kind of copies that would last, were legible, and could be made quickly

and cheaply. But the requirements of the customer became refined and he demanded

better copiers.

How Does It Work?

Xerography is an electrostatic copying process. It makes use of the basic principle

of static electricity; objects having opposite electrical charges (positive and

negative) attract and objects having the same charge (both positive or negative)

repel.

There are two commonly used xerographic copying techniques employing electrostatic

principles. One technique uses a re-usable plate or drum coated with a photoconductor,

usually selenium. The second technique uses paper specially coated with a photoconductor

such as a zinc oxide mixture. Such precoated papers are not re-usable.

Each of these xerographic techniques has been used successfully in document-copying

machines. Systems based on re-usable drums employ the "transfer electrostatic process."

The precoated paper systems use the "direct electrostatic process." References to

xerography in the remainder of this article pertain mainly to the "transfer electrostatic

process."

The heart of the selenium-based systems is an aluminum plate, or substrate, coated

with a thin film of amorphous selenium. In automatic systems, the plate is in the

shape of a cylinder, or drum. The extremely thin layer of selenium is a photoconductor,

that is, its electrical conductivity changes when it is subjected to light. The

glass-like selenium layer also accepts an electrostatic charge. If kept in darkness,

the layer retains that charge long enough to be put to use. However, if exposed

to light, the charge dissipates (leaks through the selenium layer to the aluminum

substrate) quite rapidly. If only a portion of the selenium is exposed to light,

the charge dissipates only in that area and the unexposed part retains the charge,

in other words, the amount of lateral dispersion of the charge is entirely insignificant.

The Five Basic Steps

There are five basic steps in the xerographic process. The plates are charged,

exposed, and developed. At the end of the developing step there is a powder image

on the plate. This image is then transferred to paper and fused. As a final measure

the plate is cleaned. Let us examine each step in turn (Fig. 1).

The selenium is charged by passing a wire held at high potential over its surface.

If the surface is a drum, as in automatic machines, the cylinder is rotated under

the wire.

The electrical potential on the wire is held high enough so that a corona (glow

discharge) is produced and maintained. The plate is literally sprayed with positive

or negative ions - the choice of charge depends on the type of document (a negative

or a positive) to be copied. In advanced xerographic machines, a system of wires

and grids is used to insure that the surface of the selenium receives a uniform

charge. Charging must be carried out in darkness.

In the second step, exposing, the image to be copied is projected optically to

the sensitized plate. When light from the image strikes the sensitized selenium

surface, it affects the uniformly distributed charge. Suppose, for example, the

original is an ordinary business letter. Those areas of the charged surface which

are struck by light rays reflected from the white areas of the document lose most

or all of their electrical charge. Light is not reflected from the black areas (the

type on the letter) so those areas of the selenium retain their charge. The result

is a pattern of electrical charges on the selenium plate which corresponds exactly

to the image being exposed. This pattern is called the "latent electrostatic image."

A strong electrostatic field is established between the charged and uncharged areas

of the selenium plate.

The third step in the process is to develop the electrostatic image. This is

done by pouring (cascading) a developer over the plate surface. The developer is

a granular material made up of two components: small glass or sand beads called

"carrier" and a black powder called "toner." It is in the developer that the basic

principles of static electricity are employed.

The materials for the developer are selected for their triboelectric properties.

that is, their ability to induce opposite charges of static electricity in each

other when they are rubbed together. Having opposite charges, the carrier beads

and toner adhere to each other. The charge on the toner is opposite to that which

forms the latent electrostatic image on the plate.

As the developer cascades over the selenium plate containing the latent electrostatic

image, some of the toner is dislodged from the carrier beads by a combination of

mechanical and electrical forces. It is captured by the electrostatic field between

charged and uncharged areas, and collects on the charged portions of the image area.

This black toner forms a visible, but reverse-reading, image on the plate.

The next step in the copying process consists of transferring this toner image

from the surface of the plate to a piece of paper (or to almost any other material).

This is done by placing the paper over the image area, then charging the back of

the paper with an electrical charge and bringing it in contact with the selenium

surface. The toner is thus attracted and transferred from the plate surface to the

paper.

We now have a right-reading image on paper, but the process is not yet complete.

The toner is only lightly attracted to the paper and can be brushed off easily.

It must be fixed. This can be done by fusing, that is, heating the paper and toner

so that the toner particles melt and bond to the paper. The image is now permanent.

Finally, the last procedure, cleaning, is not a part of the xerographic copying

process but is necessary so that the selenium plate can be used again to make more

copies. There is a faint residue of toner called a residual image left on the selenium

surface after the transfer step and it must be removed, usually by wiping with a

soft brush, before the selenium can be re-used.

We have described a basic xerographic process, but there are many variations

on each step of the process. For example, a corona discharge is not the only way

to sensitize a plate. It can be charged by a radioactive source or by a conductive

rubber roller. The plate can be exposed by contact, by re-flection, by projection

- or even by x-ray. The latent image can be developed by aerosols or by powder clouds,

by liquid sprays or by immersion in a liquid. The image can be transferred electrostatically,

as described, or by using an adhesive or absorptive transferring system (Fig. 2).

Finally, the images can be fused chemically, by heat, by high-pressure rollers,

or a thin plastic coat can be sprayed over the image area (Fig. 3). In the zinc

oxide and similar systems, the two steps of transferring and cleaning up are unnecessary;

the image is fixed directly on the photosensitive paper.

The Early Machines

After Xerox acquired the patent rights to xerography, the company set out to

develop an office copier. The first commercial machine was announced in 1950. It

was a manually operated machine consisting of several pieces. It had a corona device

for charging a flat selenium-covered plate, a contact box with an optical system

for exposing the plate to the image to be copied, a tray for cascade development,

and an oven for heat-fixing the image. Each step was carried out separately and

a good operator could make a copy in about two or three minutes. The company soon

saw that it would hay to speed up the process, automate it, and reduce the size

of the equipment.

The process was automated and the speed increased by replacing the flat plate

with a drum. The several process steps (charging, exposing, etc.) were arranged

at locations about the periphery of the drum so that each process step could be

carried out sequentially, but on different parts of the copy simultaneously. For

example, while one part of the drum is being exposed, another part is being developed,

the image is being transferred from another part, and the drum is being cleaned

in still another part.

Reducing the size of the equipment was another matter. The first automatic machines

were rather large and heavy - certainly not desk-top copiers.

In 1956, the company was firmly convinced that size was not the major consideration.

What was important was the performance of the equipment, the ease and speed of obtaining

copies, and copy quality. Hence, instead of concentrating on a small copier that

could be built at a cost competitive with other desk-top copiers, it built versatility

and long-run economy into a larger machine and concentrated on selling a copy service.

This machine, developed and introduced in 1960, was called the 914 Copier (because

the maximum copy size that the machine could handle was 9" x 14").

A Desk-Top Copier

Attention was next turned to the design of a true desk-top copier. The engineering

plan called for a miniaturized version of 914. At first, the problems involved in

shrinking the mechanisms of the 914 to about 1/7th of the size seemed almost insurmountable.

For example, over 1200 parts (not including nuts and bolts) had to be shrunk.

The diameter of the drum had to be reduced from 8 inches to about 4 3/4 inches.

The size and design of the drum cleaning system presented a problem in shrinking

it down to size. An entirely new cleaning system using a new, soft, non-woven fabric

was designed. Internal heat also became a design problem. The moving parts had to

be much closer to the heating unit which fuses the toner. This meant that a new

air-circulating system had to be designed to remove the heat, a system which would

allow uniform fusing but would not disturb loose paper near the machine or make

objectionable noise. These particular problems along with a good many others were

solved and the 813 Copier was put on the market near the end of 1963.

High-Speed Reproductive System

The distinction between office copying and duplicating has always been that the

duplicating process requires the preparation of an intermediate copy or master and

copiers do not. For long runs, the cost per copy with duplicators is generally less

than with copiers. In practice, duplicators are sometimes used to produce 5 or 6

copies (a costly operation) and office copiers are often used to run off copies

by the hundreds.

The gap between copiers and duplicators was bridged last fall with the introduction

of the Xerox 2400. Copies are made with this unit at the rate of 2,400 per hour

directly from the original document.

The original document is put on a curved glass platen and illuminated from below

by a bank of specially developed fluorescent lights (Fig. 4). The document is then

scanned by an optical system using a newly developed oscillating mirror. The image

is reflected through a lens to a fixed mirror which, in turn, reflects each image

onto a selenium-coated drum. The xerographic image is developed and transferred

to the paper. It is then fixed permanently on the paper by a new method called "heated

roll fusing."

To achieve speed, new developments were necessary in the optical, developing,

and fusing systems. In addition, drum speed had to be increased. The document image

is placed sideways on each third of the drum instead of the single image lengthwise

on the whole drum. In the new fast-fusing process, the paper is squeezed between

two rolls, one heated.

Search for New Products

Xerography can be used with just about any electronic system where the electrical

signal can be converted to light. It has, as a matter of fact, been used to produce

documents from the outputs of radar, digital computers, and seismic detectors .

As far back as 1950, there existed the capability to apply the principles of

xerography in a system utilizing a cathode-ray tube display to produce an image.

However, existing transmission facilities were so limited that further development

and applications to a long-range facsimile system were not practical.

In 1961 development began on a system that would overcome the shortcomings of

earlier facsimile techniques. A primary objective was to produce a system that would

rapidly provide high-quality copies on ordinary paper.

In 1964 the first commercial long-distance xerographic (LDX) facsimile system

was installed. This system, using a scanner and electronics, converts the image

to be transmitted into two-level video signals for transmission over broadband facilities,

such as microwave, special telephone lines, or cable (Fig. 5). On the receiving

end, the signals are sent to a cathode-ray tube that projects them optically onto

a xerographic drum. Then, they are reproduced by standard xerographic techniques.

Still in the research laboratory is an imaging method which is based on the deformation

(selective wrinkling) of a thin film of plastic. Called "frost," the new method

is inherently a continuous-tone process. A photoconductor is used to control the

formation of an electrostatic image and the selective deformation of a heat-softened

film. A light-scattering image is formed which can then be displayed by reflection

or transmission optics.

One final application of the principles of xerography should round out our discussion.

Xerographic toners are inert to most inorganic and to some organic etching solutions

and, therefore, can be used as a chemical resist in the preparation of printed circuits.

The technique can also be used to produce microminiature circuits.

These are but a few of the directions the research program has taken. The company

intends to continue this emphasis on "directed research and development" and to

push forward into new areas of graphic communications.

Posted September 14, 2022

|