Know Your Electronic Chemicals

|

|

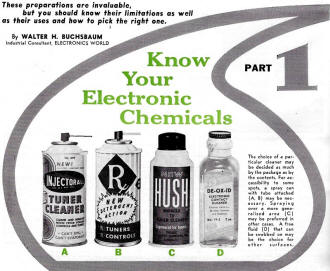

Last week I posted Part 2 of this "Know Your Electronic Chemicals" series which appeared in two 1960 issues of Electronics World. Fortunately, I was able to obtain the previous edition with Part 1 (the vintage magazines I buy typically sell for $2-$3 apiece on eBay). Many, if not most, of the chemicals presented in the articles are not used anymore, but similar types are. Interestingly but typically, almost no emphasis is placed on the use of protective clothing, goggles, gloves, gas masks, etc. A lot of people were harmed unnecessarily due to not taking basic precautions, but it just was not part of normal operating procedure. To be honest, even though I know better, other than always using eye protection when using power tools, I rarely use ear protection (except at the shooting range) or particle masks (except for when working with fiberglass insulation). My bad. Know Your Electronic Chemicals - Part 1 The choice of a particular cleaner may be decided as much by the package as by the contents. For accessibility to some spots, a spray can with tube attached (A, B) may be necessary. Spraying over a more generalized area (C) may be preferred in other cases. A free fluid (D) that can be swabbed on may be the choice for other surfaces. By Walter H. Buchsbaum - Industrial Consultant, Electronics World Whenever we visit our electronic parts distributor, we pass a large display rack full of neatly labeled bottles and cans. Often there are several such shelves and it seems that the great variety of bottles, jars, and cans would be more suitable on the prescription counter of a drugstore. This array of chemicals appears bewildering mostly because of the many different names, types, and uses advertised on their labels. Actually most of these chemicals fit into one of three main categories. They are usually cements, lubricants, or cleaners. Some of the cements may also serve as insulators, and some cleaners may contain a lubricant, but the three main categories still hold. A fourth "miscellaneous" category could be set up to cover such specialty items as enamel-wire stripper and non-slip compounds for dial cords. Paints and finishes are not properly "radio chemicals," since they are used even more widely in other industries and are also sold in painting supply and hobby stores. Category one, glues and cements, ranges from such specialized types as Bakelite cement to such commonly used glues as rubber cement. Category two is made up of many different types of lubricants and, just as in the case of the cements, the selection of the right one for each job is extremely important. In category three we have included the different cleaners and solvents, and here the damage due to application of the wrong chemical can be considerable. We would hardly solder a 0.001-μf. capacitor in place of a 0.1-μf. unit; the choice of the correct chemical can be just as important. Most of our readers are familiar with the system of electrical values and understand the difference between resistance, capacitance, and inductance, but relatively few also understand the basic chemical differences that determine the need for a particular glue, lubricant, or cleaner. This is not the place for a review of chemistry, but it is not necessary that one be a chemist in order to choose the right materials. The technician only needs to know a few fundamentals in order to pick the right compound for a particular job. The term "cleaner" covers a wide variety of completely different preparations, chemically speaking, that are intended for different applications and are not interchangeable. Tuner cleaners (preceding page) are usually of the same type as general volume-control and contact cleaner (A and B, to the right). These two types are therefore generally interchangeable. Picture-tube and glass cleaners (C) are another group entirely. Other classes include preparations for cleaning the magnetic heads of tape recorders, paint-type thinners, and household detergents. Properties of Cleaners Obviously the most important property of any liquid that we use for cleaning is its ability to dissolve and remove the substance to be taken off. This depends to some extent on what the "dirt" is and from what surface we want to remove it. For example, if we want to remove a splash of paint, we may use a common paint thinner. However, if the offending spot rests on a plastic surface, this thinner could attack the plastic as well, producing an "etched" spot that may be as bad as the original paint spot, or worse. We can see that the first consideration is to match the cleaner or solvent to both the dirt and its base. Another important consideration is the volatility, toxicity, and flammability of a particular chemical: in other words, how dangerous it is to use. What precautions must we take? Unfortunately many cleaners and solvents suffer from one or the other of these limitations. The outstanding exceptions are soap and most household detergents. Strange as it may seem, a good detergent and warm water, properly applied, can perform a great variety of cleaning chores around a service shop. Many technicians prefer to use detergent or soap with warm water for cleaning picture-tube screens and face masks, although window cleaning fluid and the special "anti-static" preparations work very well. In choosing cleaning agents for electronic service work, we must also consider their electrical properties, such as the advantage of cleaning a picture tube with a material that will reduce the static charge on the glass. This charge is responsible for attracting much dirt. In cleaning the contacts of a TV tuner, we want to make sure that the cleaner either leaves no insulating residue or else that the film left after the cleaner evaporates will be electrically conductive. A cleaning agent used to clean printed-wiring boards, on the other hand, should leave no film at all. Most of the cleaners and solvents that are sold at electronic parts distributors are specifically designed to handle a certain job. We find cleaners for magnetic recording heads, contact cleaners, potentiometer cleaners, picture-tube glass cleaners, speaker-cone cement, solvents, and so on. Few service shops carry everyone of these materials in stock and frequently one of these cleaners is called on to do a job for which it was not intended. Knowing some of the properties of a cleaner helps us decide if it is safe and worthwhile to apply a particular chemical. Some cleaning agents, such as alcohol, are very inflammable and burn even at relatively low temperatures. Others give off fumes that may tend to become dangerous. A few leave "drying spots" behind as they evaporate. Most of these troubles are avoided by the specially prepared cleaners sold through electronic parts jobbers, but even there the wrong application can be troublesome. We know of a service technician who used the thinner intended for polystyrene "dope" as an all-purpose cleaner. It worked well cleaning grease spots off a chrome-plated audio amplifier chassis. TV tuner contacts could also be cleaned with it. However, when he used it to clean the head of a tape recorder, trouble started. The felt pads that hold the tape against the head were soaked through with the thinner and, after a few hours, they fell off. New pads were glued on and the recorder was delivered. However, a few drops of glue had been used to lock the head alignment screws in place, and this glue was loosened by the thinner. Within a few weeks the recorder was returned by the unhappy customer because of "weak sound." It was found that the head alignment was off. By that time the technician had a small stock of the most frequently used cleaners and other chemicals so that he could be sure that the right material was used each time. Table 1 - Many chemicals that do not have to be purchased as special preparations are useful. They are listed here, with applications and limitations. Contact Cleaners Probably 50% of all troubles in potentiometers, switches, and tuners are due to dirty contacts. It is therefore not surprising that a host of specially prepared cleaning agents is available just for this purpose. General Cement's "De-Ox-Id"; Walsco's "No-Ox"; "Quietrole"; Electronic Chemical's "No-Noise"; "Hush"; and a number of similar preparations are all specially designed to deal with the contact cleaning problem. They all operate effectively on contacts and potentiometers, but should not be used for cleaning glass, printed-wiring boards, or other exterior surfaces because they leave a residue. Our readers may ask at this point what is so special about contacts that they require a particular chemical? Could we not use carbon tetrachloride or alcohol? The answer is that these simple cleaners could be used. For that matter, even soap and water would have some effect. However, to avoid deterioration of the contacts, a special preparation is better. Most switch and tuner contacts are either solid coin silver or are at least heavily silver plated. Silver oxidizes, as is apparent by the black coloring that develops on it. The oxidized film is a poor electrical conductor. When even small currents are switched through these contacts, some arcing is inevitable, and this promotes further oxidation. Eventually the contacts become intermittent. In addition to the oxidation of the contact surface there is mechanical wear. If the contacts are lubricated to avoid this wearing process, the lubricant gets saturated with dust until a gritty mixture clings to the contact area. This actually accelerates wear. From this description we see that a cleaner should really do several jobs. It must dissolve the lubricant and wash away the dirt. Then it must be able to dissolve the oxidized coating. After that the contacts should be clean, and now lubrication is needed. Many of the prepared contact cleaners leave a film behind that serves to lubricate the wearing surfaces. To maintain good electrical contact, this film should be conductive. Irrespective of the type of cleaner used, the applicator is important. Never, never, under any circumstances should contacts be scraped with a metal instrument. Scraping can not only remove dirt and oxide but can also damage the silver plating and wreck the wearing surface. The same goes for the practice of using sandpaper. This habit stems from the early days of electricity when copper contacts were used. In practically all electronic switches, silver or (on more expensive items) rhodium contacts are used: these should be cleaned only with chemicals. The best way of applying a cleaner is by using a fine artist's brush, cleaning tissues held in tweezers or - the simplest - "Q-Tips" (cotton pads wound on small wooden sticks). The most effortless way to clean TV tuner contacts is to apply the cleaning agent without removing the chassis. This is often possible if we use one of the special cleaning agents that is available in a spray can, with a special nozzle or injecting needle. The cleaning agent is sprayed directly into the contact area and, since the agent contains a conducting lubricant as well as a cleaner, noisy contacts are usually "quieted down." In a similar manner, noisy volume controls can be cleaned by forcing the liquid cleaner in through the shaft bearing. Whenever such a "quickie" method is used, it is important that the contacts be moved in both directions to clean and lubricate all surfaces properly. A TV tuner should be switched through all channels at least four or five times, and a potentiometer should be turned at least as often, from one extreme of its rotation to the other. Basic Cleaners The technician who is a long way from a well-stocked parts supplier and who finds himself suddenly out of the needed cleaning agents can resort to a number of common cleaning materials - that can be adapted to fill almost any need. Some of these are to be found in most homes so that when a house call is made, one can sometimes obtain them from the efficient house-wife (poor practice, of course, except in an emergency). A list of some of these cleaners with their recommended use in electronic work is shown in Table 1. Remember that, unlike the preparations obtainable through a regular electronic supply house, the strength and purity of these items is usually unknown. They may therefore be unsuitable for a particular use. A review of these common cleaning agents shows that most of them are suitable only for general cleaning of chassis, picture tubes, and cabinets. The specific requirements for contact or potentiometer cleaners are not met by anyone of them. Two items, gasoline and paint thinner, are not recommended for electronic work because they are dangerous and not really suitable for any application. Both have a tendency to leave a film that often contains chemically active residues. Most rubbing alcohol is simply denatured alcohol with possibly some aromatic ingredient added. This can be used for cleaning off grease. Occasionally the alcohol is mixed with mint or other oils, and the latter can then leave undesirable residues. It is usually safest to try a questionable cleaner out first on a sample spot, a small area not normally visible, or on a piece of dirt scraped from the area we want to clean. If the reader finds himself without a good contact cleaner he can use alcohol or carbon tet to remove the dirt first, provided that the contacts are accessible enough to be wiped with a "Q-Tip" or similar wiper. Then a mild silver polish can be applied carefully and quickly removed. This takes care of the oxidation - but it is important that any residue of the silver polish be completely removed. This can be done either by rinsing the area with water and drying it off with air pressure, or by using alcohol again. Next, the contacts should he lubricated, but never with machine or household oil. In the absence of a good contact lubricant, "Crisco" or a similar vegetable shortening can be used in an emergency. Be careful not to use too much and apply the shortening only to the contact area. Such "homey" cures may come in handy when a noisy TV tuner is encountered, but they cannot be used easily on a potentiometer. Unless we are willing to disassemble the pot, the only remedy, short of replacing it, is to use one of the specially prepared cleaners. Most of these chemicals are sold with either a long, thin nozzle or needle with a pressure can, or else a special plastic nozzle that fits over the shaft is provided. These applicators help to get the cleaner directly to the moving contact area where the trouble really is. Recording Head Cleaners A whole group of special-purpose preparations is available for cleaning magnetic recording heads. Here the cleaning agent must remove the iron-oxide deposits that collect at the head and should leave a lubricating film to reduce tape wear. At the same time, the cleaner should not be damaging to the felt pads or the cement that holds them. It should not attack the plastic material of the recorder case, the epoxy which is usually part of the head, nor should the film left by the cleaner be harmful to the tape itself. Magnetic head cleaners offered by parts jobbers under various trade names all fulfill these requirements. Some cleaners like E. L. Hern's "X-Sol," are available with a cotton wick that can be inserted into the tape mechanism and pulled through just like the recording tape. This makes for a very simple yet effective cleaning procedure. The wick is squeezed out automatically when it is returned to the bottle and, after a while, the collection of iron oxide at the bottom of the bottle signals that it is time to get another bottle. Conclusion A little understanding of the basic chemistry of cleaning agents is helpful for anyone who services electronic equipment. Common household cleaners can be used for some jobs and can often serve, in a pinch, when the right chemicals are not available. The specially prepared cleaners still give the best results. For switches, tuners and any other contacts, a special contact cleaner that also deposits a lubricating film should be used whenever possible. For noisy potentiometers, a special cleaner and applicator are a necessity. For cleaning the delicate and expensive heads of magnetic tape recorders, only a prepared magnetic head cleaner should be used. (Concluded next month)

Posted June 21, 2018 |

|